This is a demo store. No orders will be fulfilled.

Eye Bolts For Lifting No Shoulder Fully Threaded Shank

Eye Bolts For Lifting No Shoulder Fully Threaded Shank come in a variety sizes, materials, platings/coatings. Capacities listed are for vertical lifting only. These American Made No Shoulder (Plain) Eye Bolts should not be used in Angular lifts. See individual eye bolts for rating information.

Key Features

- Materials and Platings/Coatings:

Plain Self-Colored Steel

Zinc-Plated Steel

Hot-Dipped Galvanized steel

Alloy Steel 8620

316 Stainless Steel

304 Stainless Steel

- Standard : American Standard and Metric

Domestically Produced

Domestically Produced

Applications

- The receiving hole should be counter-sunk and be free and clear of any debris to assure proper seating.

- LOADS SHOULD ALWAYS BE ALIGNED TO THE PLANE OF THE EYE, not at an angle to the plane. A steel washer or spacer may be used in conjunction with Shoulder Eyebolts to attain proper load alignment. The thickness of the steel washer or spacer must not exceed one thread pitch.

- Angular lifting should be avoided. Angular lifts significantly reduce rated capacities.

- Check seating after applying an angular lift since the initial lift may cause the bolt to back away from the load. If such occurs, the Eyebolt should be unloaded & properly reseated.

- Plain Eyebolt tapped holes are to be threaded for full length engagement of the Eyebolt.

- Plain Eyebolts must have full thread shank engagement, allowing for one-half turn for proper eye-alignment to obtain rated capacities.

-

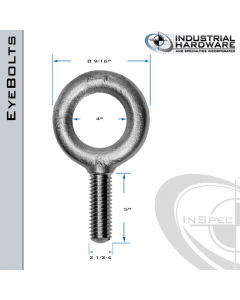

Sku #: 59A-K2017-HDG

K2017-HDG: 2-1/2-4 x 5 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $591.69 Regular Price $842.63 -

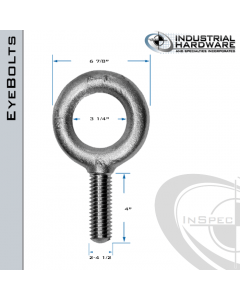

Sku #: 59A-K2016-HDG

K2016-HDG: 2-4-1/2 x 4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $139.99 Regular Price $199.36 -

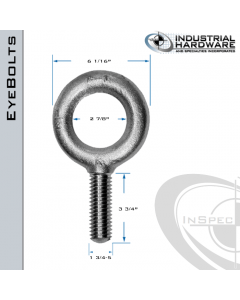

Sku #: 59A-K2015-HDG

K2015-HDG: 1-3/4-5 x 3-3/4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $107.91 Regular Price $153.68 -

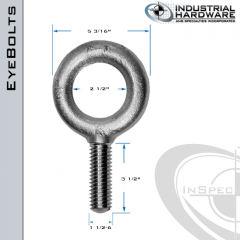

Sku #: 59A-K2014-HDG

K2014-HDG: 1-1/2-6 x 3-1/2 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $70.21 Regular Price $99.99 -

Sku #: 59A-K2012-HDG

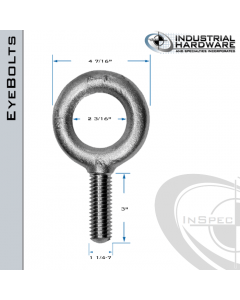

K2012-HDG: 1-1/4-7 x 3 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $41.89 Regular Price $59.65 -

Sku #: 59A-K2011-HDG

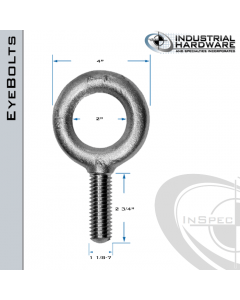

K2011-HDG: 1-1/8-7 x 2-3/4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $31.65 Regular Price $45.07 -

Sku #: 59A-K2010-HDG

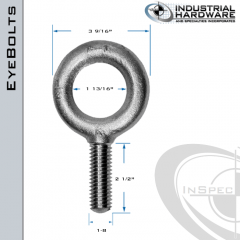

K2010-HDG: 1-8 x 2-1/2 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $22.94 Regular Price $32.66 -

Sku #: 59A-K2009-HDG

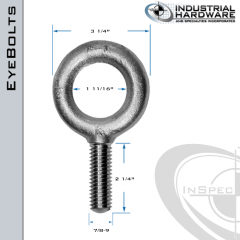

K2009-HDG: 7/8-9 x 2-1/4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $17.54 Regular Price $24.98 -

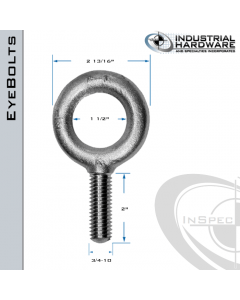

Sku #: 59A-K2008-HDG

K2008-HDG: 3/4-10 x 2 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $13.88 Regular Price $19.77 -

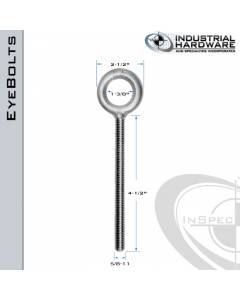

Sku #: 59A-K2007-4-1/2-HDG

K2007-4-1/2-HDG: 5/8-11 x 4-1/2 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $14.91 Regular Price $21.24 -

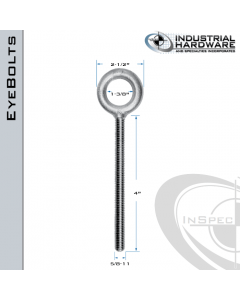

Sku #: 59A-K2007-4-HDG

K2007-4-HDG: 5/8-11 x 4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $14.79 Regular Price $21.07 -

Sku #: 59A-K2007-HDG

K2007-HDG: 5/8-11 x 1-3/4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $10.74 Regular Price $15.30 -

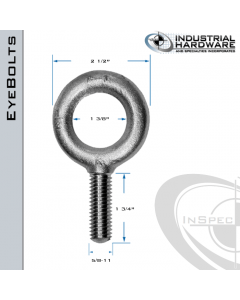

Sku #: 59A-K2005-HDG

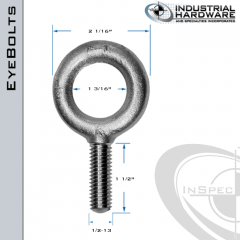

K2005-HDG: 1/2-13 x 1-1/2 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $6.82 Regular Price $9.71 -

Sku #: 59A-K2003-HDG

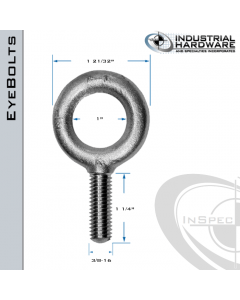

K2003-HDG: 3/8-16 x 1-1/4 in Long Full Thread Plain Pattern Eyebolt Carbon Steel - Made in the USASpecial Price $6.37 Regular Price $9.07