This is a demo store. No orders will be fulfilled.

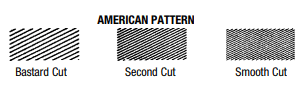

American Pattern

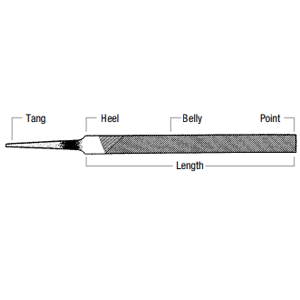

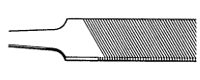

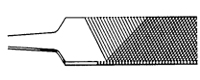

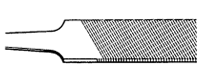

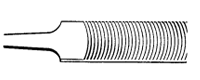

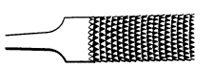

Choosing an American Pattern FileSelecting the proper file for your application is essential if your going to achieve the desired result for your job. When selecting the proper file you most consider its shape, size, tooth type, and coarseness. The size and the coarseness of the file are directly related. Larger files will remove more stock but will also leave your project with a coarse finish, while smaller files will remove less stock, but will leave a finer, smoother finish. Parts of the File Coarseness Kinds of Teeth Shape |

|

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Sku #: 3HN-21743N

Nicholson File #21743N 6 in. Double Extra Slim Taper File-Red HandleAs low as $42.86 -

Sku #: 3HN-21874N

Nicholson File #21874N 6 in. Double Extra Slim Taper File without HandleAs low as $37.96 -

-

-

-

-

-