This is a demo store. No orders will be fulfilled.

10-24 UNC x 0.285 WireSert Threaded Insert for Metals - Free-Running - 18-8 Stainless - 12/pkg

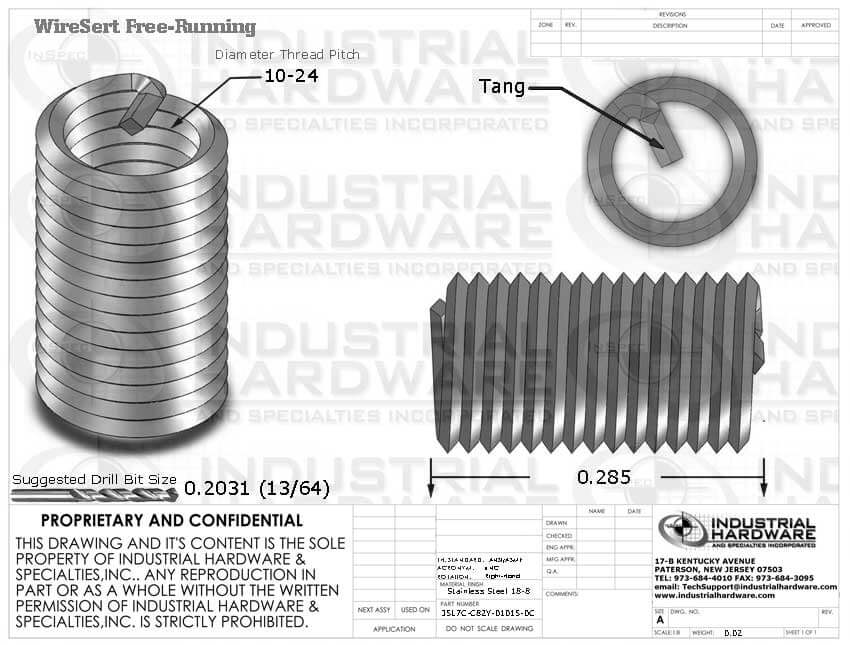

The 10-24 UNC x 0.285 WireSert Threaded Insert for Metals - Free-Running - 18-8 Stainless - 12/pkg is designed to quickly repair damaged threads in soft metals such as: aluminum, cast iron, magnesium, etc. This free-running insert has a 10-24 UNC Right-Hand internal thread and is 0.285 long.

10-24 UNC x 0.285 WireSert Threaded Insert for Metals - Free-Running - 18-8 Stainless - 12/pkg

WireSert inserts also known as wire or helical threaded inserts quickly repair or reinforce tapped holes in soft metals. Manufactured from Stainless Steel 18-8, WireSert inserts provide strong internal threads that are corrosion resistant and withstand temperatures to 800 degrees fahrenheit. This free-running insert has a 10-24 UNC Right-Hand internal thread and is 0.285 long.Free-Running inserts should be larger in diameter than the tapped hole. Compression during installation provides maximum surface contact between the flanks of the wire insert and the tapped threads. The flexibility of WireCert inserts enhance the load bearing capacity by deflecting the residual forces into a helical, which is dispersed into the wall of the tapped hole. Order today from Industrial Hardware and Specialties.. Order today from Industrial Hardware and Specialties.

Features

- Quickly repair damaged threads in soft metal

- Protect tapped holes from stripping and wear

- Made from corrosion resistant 18-8 stainless steel

Applications:

- Soft metals: aluminum, cast iron, magnesium, etc.

Installation:

- Drill out the hole with the specified drill

- Confirm that the thread and pitch of the bolt match the tap.

- Tap the hole with the specified tap.

- Set the stop on the installation tool so the tang is centered in the slot.

- Wind the insert into the hole with a slight downward pressure until 1/4 to 1/2 turn below the surface.

- Remove the tang by placing the tang break tool (or installation tool) on top of the tang and striking firmly with a hammer.

| Application | Metals |

|---|---|

| Material | Stainless Steel 18-8 |

| Insert Style | Free-Running |

| Drive | Tang |

| ID Thread Rotation | Right-Hand |

| ID Thread Standard | ANSI/ASME |

| ID Acronym | UNC |

| OD Thread Rotation | Right-Hand |

| OD Thread Standard | ANSI/ASME |

| Flange/Flush | Flush |

| Inside Thread | 10-24 |

| Length | 0.285 |

| Drill Size | 0.2031 (13/64) |

| Drill Size | 0.2031 (13/64) |

| Plug Tap Size | 10-24 |

| Bottoming Tap Size | 10-24 |

| Tang Break Off Tool - Solid Punch | 35L7H8-197 |

| Electric Mandrel | 35L7H4-010C |

| Pneumatic Mandrel | 35L7H6-010C |

| Pneumatic Prewinder | 35L7H7-010C |

| Pneumatic Assembly | 35L7H5-010C |

| Threaded Prewinder Install Tool | 35L7HB-010C |

| Threaded Mandrel Install Tool | 35L7HA-010C |

| Chrislynn Part Number | 83112 |